Zero Cow Factory, an India-based biotechnology company that produces sustainable animal-free milk proteins and dairy products using bioengineered microbes and precision fermentation, has announced raising $4 million in a seed round. Green Frontier Capital, GVFL, and pi Ventures led the funding round, with Pascual Innoventures participating. The company aims to accelerate its R&D efforts, scale up production capacity, and obtain regulatory approvals to enter the market.

We are excited to partner with our investors’ outstanding setup and combine them with our talented team, which positions us uniquely to lead the way in building a global dairy 3.0 that is animal-free, sustainable, and scalable.

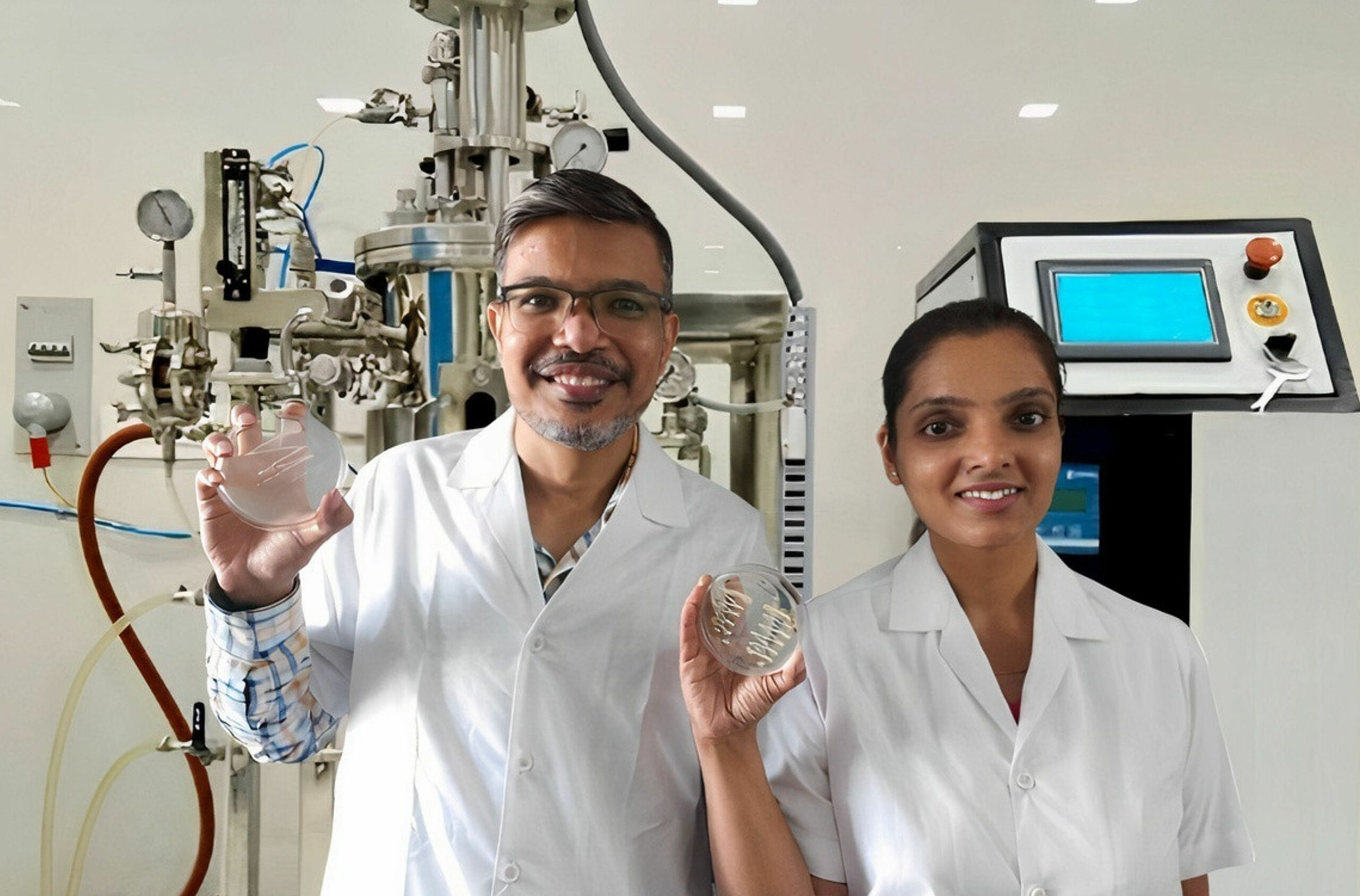

Sohil Kapadia, Co-founder and CEO of Zero Cow Factory.

Marketing In Asia (M.I.A) personally gathered responses from Sohil Kapadia and Parini Kapadia, the founders of Zero Cow Factory, to shed light on their patented technology for milk production and their future plans.

Patented technology for milk production

Zero Cow Factory uses a combination of genetic modification, strain engineering, precision fermentation, and downstream processes to produce nature-identical animal-free dairy proteins such as casein and whey in a laboratory environment. The company’s technology is different from other biotechnology-based milk production methods, such as cell-based technology. Zero Cow Factory’s animal-free food ingredients produced via precision fermentation is considered a novel ingredient in most countries for regulatory approval because it is produced differently.

We are developing a technology to reproduce milk proteins to craft real dairy products that are ethical, safe, delicious, and identical to cow milk but without any animal involved.

Parini Kapadia, Co-founder and CSO of Zero Cow Factory.

Obtaining regulatory approvals

The approval timeline and assessment process for animal-free food ingredients produced via precision fermentation varies from country to country. Zero Cow Factory is taking steps to follow the food regulatory guidelines and conduct advanced tests related to toxicology, allergy, purity, and other aspects to ensure the safety and quality of its milk-based products. Presently, it is a new category, and only 3–4 countries have approved such products.

Overcoming challenges

During the development of the technology, the company faced challenges in identifying which microorganisms worked best for its targeted proteins. The company overcame this challenge by trying different microorganisms, optimising processes at each stage, and iterating various protocols to standardise them.

Scaling up production and increasing market penetration

Zero Cow Factory plans to speed up its R&D efforts, scale up production capacity, and obtain regulatory approvals to hit the market with its new funding. The company is yet to figure out the right product-market fit that works best for it in the near future. It plans to compete with traditional dairy producers and plant-based milk alternatives by developing a new alternative to cow’s milk protein that replicates its taste, texture, nutrient profile, and appearance.

Zero Cow Factory’s use of cutting edge bioengineering and life science based technologies to change the future of food production aligns well with our investment thesis of backing disruptive tech ventures. We have been impressed by Sohil and Parini and look forward to working with the entire team at Zero Cow Factory to bring lab-grown dairy products to the masses.

Shubham Sandeep, MD at pi Ventures

Addressing consumer concerns

Precision fermentation technology is a technology that has been around for 30 years, is entirely safe, and is used in dozens of products people interact with every day. From all sorts of enzymes used in food production, common vitamins used to fortify foods, natural flavours, insulin for diabetes patients, and most importantly, rennet (also called chymosin), a key ingredient used in cheese manufacturing today, is derived mostly using precision fermentation. The company believes that consumer awareness and marketing will play a significant role when more and more similar products are available in the market.

Ethical considerations

Zero Cow Factory takes ethical considerations into account when developing its products, such as concerns about animal welfare and environmental sustainability. Cow burps are a major contributor to climate change, and it is estimated that each year, a single cow generally belches about 220 pounds of methane. As a global average, approximately, dairy milk is responsible for adding 1.39 kg of CO2-equivalents to the atmosphere for every litre produced, and the overall carbon footprint of 1 kg of cheese is estimated at 14 to 51 kg of CO2-equivalents.

With cattle being the No.1 agricultural source of greenhouse gases, precision fermentation startups have the potential to disrupt the dairy industry globally. If the world (and India) has to achieve its net zero goals, there needs to be a pivot rather quickly to sustainable solutions like precision fermentation and, in that regards, Zero Cow Factory, is working assiduously on developing its own proprietary A2 casein-based solution, a weakness which plant-based ingredients have not yet been able to address successfully.

Sandiip Bhammer, Co-Managing Partner and Founder at Green Frontier Capital

With limited resources and a growing population, traditional methods of dairy farming are unsustainable in the long run due to their severe impact on land, freshwater, and climate. We believe that going forward, most of the proteins for milk, cheese, and other dairy products will be produced in a lab. The company’s patented technology produces dairy proteins without any animals being involved, as traditional methods of dairy farming are unsustainable in the long run.

Zero Cow Factory is at the forefront of innovation in the alternative protein space. Their mission is to drastically reduce greenhouse gas emissions by providing a sustainable solution that is better for the planet, people and animals.

Kamal Bansal, MD at GVFL

Also read: This father-son duo are producing sustainable animal feeds using organic waste

Zero Cow Factory’s innovative technology has the potential to revolutionise the dairy industry, providing a sustainable and animal-free alternative to traditional dairy production methods. With its recent funding, the company plans to scale up its production and penetrate the market, offering consumers a new way to enjoy dairy products while promoting animal welfare and sustainability.

Legal Disclaimer: The Editor provides this news content "as is," without any warranty of any kind. We disclaim all responsibility and liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. For any complaints or copyright concerns regarding this article, please contact the author mentioned above.